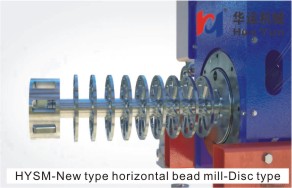

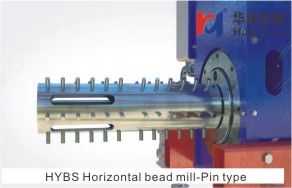

Horizontal bead mill

Horizontal bead mill is a continuously-processing grinding and dispersing machine with a horizontal chamber. It is the most widely used, most advanced and most efficient grinding equipment. Huayun horizontal bead mill can be divided into disc type bead mill, pin type bead mill and turbine type bead mill based on the shape of the working part for the grinding medium.Type choosing

Click for more info

Working principal

Horizontal bead mill mainly drives the dispersing shaft for high-speed movement by the motor. Under the action of the dispersing disc, the grinding medium performs high-speed movement, and the friction and shearing force make the material to be ground and dispersed repeatedly. Finally, the grinding medium is separated by the dynamic separator and the screen to make the qualified material flow out from the discharge pipe. Meanwhile the material is pumped into the chamber through the feeding system constantly, thereby realizing long-term continuous grinding work!

System introduction

The feeding system

The feeding system consists of a transfer pump and a pipe,material passing stainless steel hose pipe,and the material is pumped from the rear end of the cylinder and the qualified material flows out from the front end. A pneumatic diaphragm pump or a hose pump is commonly used for conveying material, and the flow rate of the pump can be automatically adjusted.

Thermal design for grinding cylinder

In the grinding process, a large amount of heat is generated. The Huayun horizontal bead mill designed the grinding cylinder with a jacket, forced cooling through a spiral diversion tank.According to temperature requirements of the materials and the volume of the bead mill,you can choose different cooling machine.The optional size of the cooling machine can realize the control of the grinding temperature and protect the characteristics of different material. The bottom of the cylinder support is equipped with casters. When the connecting bolts are removed, the grinding cylinder can be pulled out for maintenance or cleaning.

Mechanical seal

Huayun disc bead mill adopts double mechanical seal to make it fully enclosed, thus eliminating material leakage during production in order to reduce pollution.

Each sand mill is equipped with an organic sealing tank.The cooling liquid is pumped in to lubricate and cool down the mechanical seal circularly by the electric pump.You can choose different cooling liquid according to different grinding material.

Transmission component

Due to the high speed of the horizontal bead mill, only one level of belt drive can reduce the speed of the motor to the required speed.The main motor is mounted on the motor board, and the motor is lifted and lowered by adjusting the bolts to facilitate the exchange and tension of the V-belt.

Application industry

Huayun horizontal bead mill is widely used in coatings, dyes, inks, photosensitive materials, pesticides, medicine, lithium batteries, nano new materials, carbon nanotubes, cosmetics, graphene and other industries.

Strong applicability

In order to ensure the adaptability of the products, Huayun can provide various choices of grinding chambers/dispersion discs/rods/turbine/ transport pumps of different materials;we can also supply control operation box, frequency converter, plc intelligent control system, electric contact equipment and other optional accessories according to customer’s requirements.

Complete category

Huayun disc bead mill fully meets the specifications of 10L to 300L, with complete product type and wide application range.

Pictures Pictures